- Home

- Products

Products

Product Range

With decades of experience in the steel industry, Sakthi Steel Industries Limited has earned a reputation for excellence. This is why we are the preferred partner for construction and infrastructure projects across India.

MILD STEEL BILLETS

Sakthi Group, Manufactures a wide range of Continuously casted Billets in its Steel Plant. By incorporating state-of-the-art technology, employing expert professionals, and leveraging years of knowledge and experience, we ensure the production of defect-free casting billets that meet and adhere to the highest industrial standards.

TMT RINGS

As part of a forward integration and to add value to the Construction Process Chain, ready to use TMT Rings have been introduced with a focus on saving cost and time. Made at the same plant where SRI DURGA TMT is produced, these TMT Rings help reduce the construction time significantly.

Different Sizes of TMT Bars

SRI DURGA TMT IS THE STEEL FOR THE SUPERIOR QUALITY STRENGTH

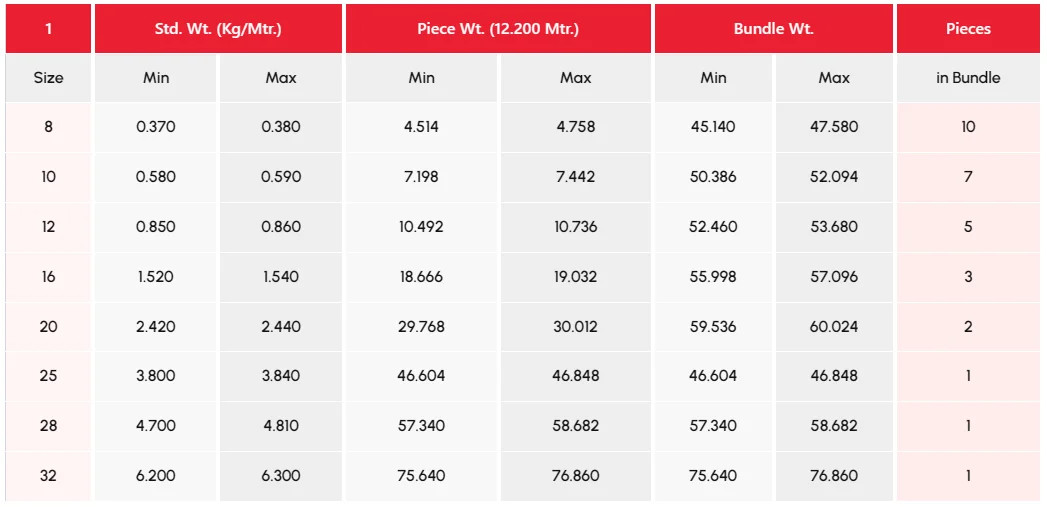

SRI DURGA TMT Standards – Mechanical & Chemical Specifications

With decades of experience in the steel industry, Sakthi Steel Industries Limited has earned a reputation for excellence. This is why we are the preferred partner for construction and infrastructure projects across India.

| 1 | Std. Wt. (Kg/Mtr.) | Piece Wt. (12.200 Mtr.) | Bundle Wt. | Pieces | ||||

|---|---|---|---|---|---|---|---|---|

| Size | Min | Max | Min | Max | Min | Max | in Bundle | |

| 8 | 0.370 | 0.380 | 4.514 | 4.758 | 45.140 | 47.580 | 10 | |

| 10 | 0.580 | 0.590 | 7.198 | 7.442 | 50.386 | 52.094 | 7 | |

| 12 | 0.850 | 0.860 | 10.492 | 10.736 | 52.460 | 53.680 | 5 | |

| 16 | 1.520 | 1.540 | 18.666 | 19.032 | 55.998 | 57.096 | 3 | |

| 20 | 2.420 | 2.440 | 29.768 | 30.012 | 59.536 | 60.024 | 2 | |

| 25 | 3.800 | 3.840 | 46.604 | 46.848 | 46.604 | 46.848 | 1 | |

| 28 | 4.700 | 4.810 | 57.340 | 58.682 | 57.340 | 58.682 | 1 | |

| 32 | 6.200 | 6.300 | 75.640 | 76.860 | 75.640 | 76.860 | 1 | |

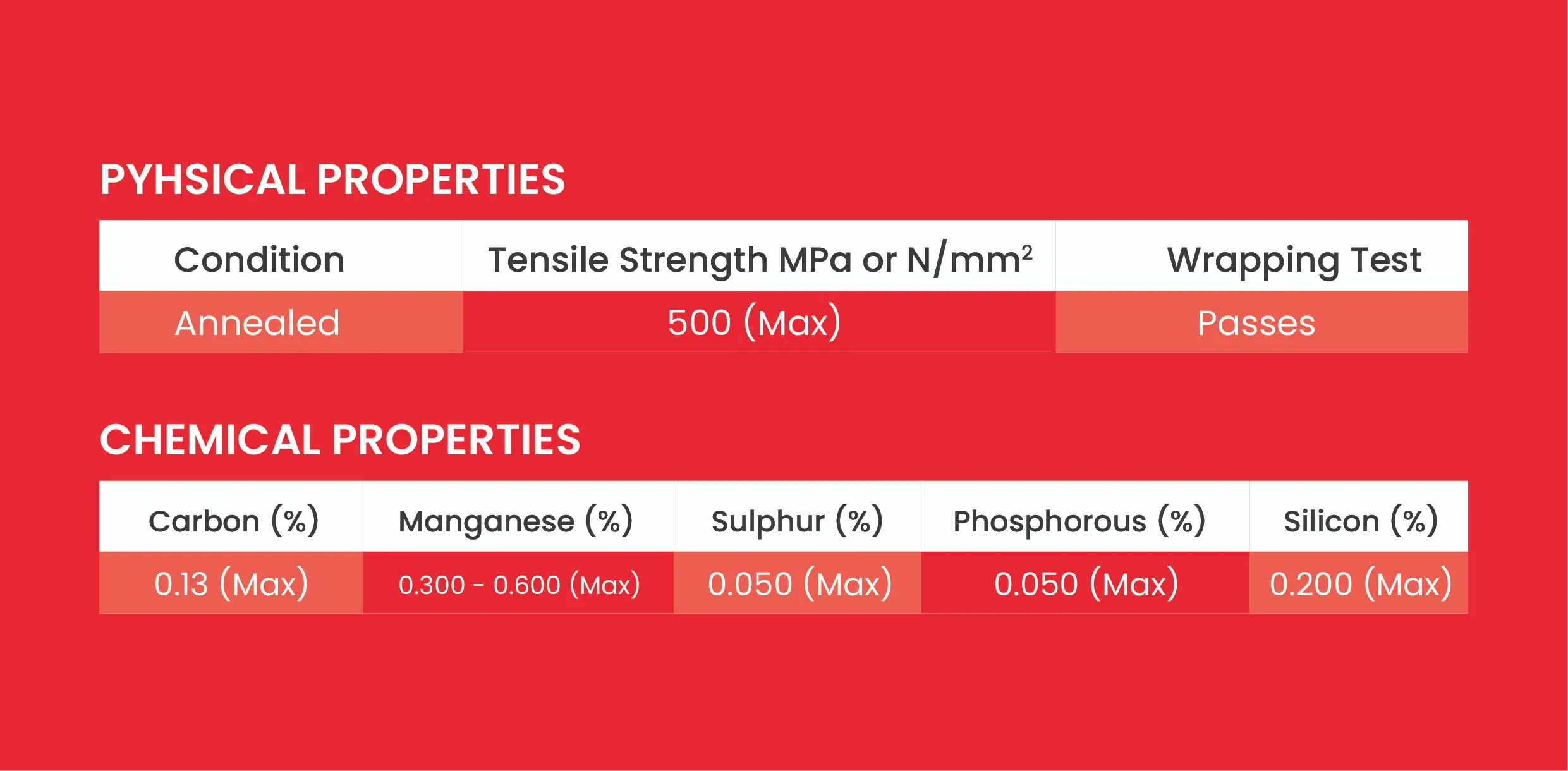

| Properties | IS:1786-2008 | SRI DURGA TMT | Constituent(%) | IS:1786-2008 | SRI DURGA TMT |

|---|---|---|---|---|---|

| Yield Stress-N/mm2(min) | 550 | 570 | Carbon(Max) | 0.30 | 0.25 |

| Tensile Strength-N/mm2(min) | 585 | 630 | Sulphur(Max) | 0.055 | 0.045 |

| TS/YS Ratio(Min) | 1.06 | 1.10 | Phosphours (Max) | 0.055 | 0.045 |

| Elongation %(min) | 10.0 | 16.0 | S & P(Max) | 0.100 | 0.080 |

| Total Elongation %(min) | NA | 570 | Carbon(Max) | 0.30 | 0.25 |